How to Calculate Linear Feet

When you are preparing a home improvement project, purchasing materials, or just estimating the cost, you will save time and money if you know how to calculate the linear feet. One of the most used measurements which is easiest to master, yet one of the most confused is linear feet.

- What linear feet means in everyday terms

- When you use linear feet versus other measures

- Tools and preparation before you measure

- How to calculate linear feet for multiple runs and corners

- Special cases: curved runs and irregular shapes

- Converting linear feet to other units

- Ordering materials and accounting for waste

- Common mistakes to avoid

- Practical examples you can follow

- Conclusion

- Frequently Asked Questions

- What amount of waste should I order in calculating linear feet?

- What is the formula to use in changing the linear feet to square feet?

- Is it possible to estimate concrete or masonry by the use of linear feet?

- Are there Internet tools to check the calculation of the linear feet?

- What is the mistake that people normally commit when determining linear feet?

If you are thinking how to calculate linear feet, this guide walks you through explanations, real world examples, and practical tips so you can measure correctly and order the right amount of material for trim, baseboard, fence rails, tubing and many other supplies.

What linear feet means in everyday terms

Linear feet is simply the measure of length in feet along a straight line. If you lay a tape measure down and read off the number in feet, you have measured linear feet. If you need baseboard for three walls that are ten, twelve and eight feet long, then your total is thirty linear feet. When you know how to calculate linear feet, you can avoid buying too little or ordering overpriced bundles.

When you use linear feet versus other measures

You use linear feet whenever your materials are measured in one direction only. For instance, when you order a roll of carpet trim, a length of handrail, or a length of metal flashing, you almost always use linear feet. If you are ordering flooring tiles or paint, you use square feet and gallons respectively because those products cover area or volume.

In lengths and widthes of parts like in decking with boards, you might require linear and square feet to estimate the material. You can use the following as an example, to determine the amount of decking material you require, you may work out the number of linear feet of edge trim that you require, and then multiply plank coverage by square feet.

It is convenient to know when to change linear feet to square feet. If you buy quarter round or flat stock that is to measure linear feet but you need to estimate weight, you may multiply linear feet by cross section area or by thickness to arrive at volume or weight estimates. Tools such as the TogCalculator Concrete Weight Calculator are useful when your linear length feeds into a volume estimate for things like poured concrete curbs or narrow footings. Use the calculator to check the volume and weight if your linear measurement becomes part of a three dimensional calculation.

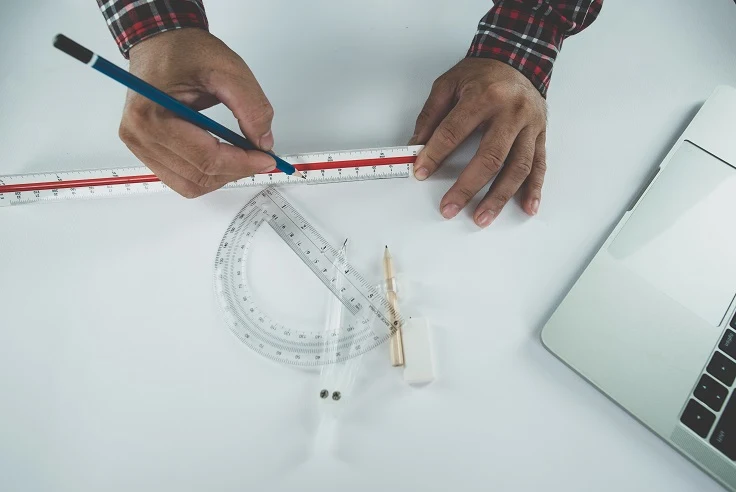

Tools and preparation before you measure

In outside measurements, take a helper with you when you are alone, since long tapes are more convenient with two men. Draw a simple sketch of the area and indicate every wall with a letter or number. Record the measurements in feet and inches in a list. Divide by 12 inches in a foot when adding runs together or by conversion at the end. In case you use decimals, 12 inches are one foot and therefore, it is better to divide the inches by 12 to convert.

Provided that your project will require exact ordering (custom rail stock or specialty trim), then make sure that you triangulate measurements and then have an online calculator of linear feet to be sure of totals. For projects that include poured concrete elements where length determines volume, also consider checking volumes and weight with an online tool. The TogCalculator Concrete Weight Calculator can help you convert a linear measurement and cross section into volume and expected weight when planning concrete deliveries for footings and curbs.

How to calculate linear feet for multiple runs and corners

Most real jobs involve multiple runs. For example, imagine a rectangular room with walls measuring ten feet by twelve feet. Add the lengths of all four walls to find the perimeter, which is the linear feet required for baseboard. That would be ten plus twelve plus ten plus twelve, equaling forty four linear feet. If you have door openings where you do not need baseboard, subtract the widths of the doors from the total linear feet.

Corners and angles do not change how you calculate linear feet because you simply measure along the face of the material from one end to the other. For mitre cuts or corners, you may need extra length to account for waste, so we will cover ordering allowances below.

Special cases: curved runs and irregular shapes

Curved walls and irregular shapes are easy to handle with a little patience. For gentle curves, you can measure by walking a flexible tape along the curve and reading the linear length directly. The smaller the segments, the more accurate your total will be.

Converting linear feet to other units

To convert linear feet to board feet or volume, multiply the linear feet by cross sectional area. Board feet is a common measure in lumber where one board foot equals one foot by one foot by one inch. If you are working in metric units, convert feet to meters and proceed using meters for volume calculations. When length is part of a three dimensional calculation, such as a concrete footing, you will multiply the linear feet by the cross section area of the footing to get volume.

Ordering materials and accounting for waste

Ordering the right amount of material requires planning for cuts, defects and mistakes. For tile or stone where pattern matching matters, you may need even more. Always round up to full pieces when the supplier sells materials in fixed lengths. If your total linear feet result in 10.2 pieces, you will have to buy 11 pieces in practice. Talk to your supplier about returning unused full length pieces. Some stores accept returns on unopened bundles, which can reduce waste costs if you over order by mistake. Another tip is to lay out your cuts before ordering. Around 30% of all building materials delivered to a typical construction site end up as waste.

Common mistakes to avoid

Always measure every run. Another mistake is forgetting to subtract openings, such as doors, unless the material will be installed there. Do not forget to add waste allowance especially if the project has many angles or diagonal cuts.

Failing to convert inches into feet consistently causes errors. If you mix decimals and fractions without converting, you can accidentally underorder. When in doubt, write every measurement in inches and convert to feet at the end. This reduces the chance of small arithmetic errors.

Practical examples you can follow

Example one is a small hallway that needs new quarter round trim. The hallway is eight feet long and both sides need trim, so measure both sides for a total of sixteen linear feet. Add a small amount to account for mitre cuts and you may order eighteen linear feet to be comfortable.

Example two links linear feet to volume. You plan a 50 linear foot concrete curb that is six inches wide and six inches tall. Convert six inches to feet, which is zero point five. For a curb, the cross section area is zero point five times zero point five, which equals zero point two five square feet. Multiply by fifty linear feet to get twelve and a half cubic feet. Divide by twenty seven to convert to cubic yards which tells you how much concrete to order. For confidence, you can cross check these numbers with an online tool. The TogCalculator works well for confirming volume and weight when linear measures become a concrete order.

Conclusion

Measure twice and cut once. Label every measurement and do the arithmetic methodically. Keep a small sketch so you can explain your numbers to suppliers. When buying materials, call the supplier ahead to confirm package lengths and return policies. If your project touches concrete or masonry and the linear measurement becomes part of a volume calculation double check with a calculator to avoid under ordering. The extra care upfront prevents delays and additional hauling costs.

Tools like the TogCalculator help you answer queries as to how to calculate linear feet, so you can plan delivery and costs accurately.

Frequently Asked Questions

What amount of waste should I order in calculating linear feet?

Ten percent of straight runs should be added as a good baseline. In projects with numerous angles or mitre cuts, one should increase the cost by fifteen to twenty percent.

What is the formula to use in changing the linear feet to square feet?

Divide the width of the material in feet by the width in feet. As an example, the height of trim is four inches in length, and thirty linear feet is approximately ten square feet.

Is it possible to estimate concrete or masonry by the use of linear feet?

Yes. In case the cross section of a concrete or masonry element is constant, multiply the linear feet by the cross sectional area to obtain the volume. Calculate the cubic feet to cubic yards with the help of a calculator and then order concrete.

Are there Internet tools to check the calculation of the linear feet?

Yes. Online linear feet calculators are abundant and allow the entry of runs and widths and give back totals. The TogCalculator Concrete Weight Calculator is also a useful tool to use on projects that deal with concrete volume and weight, as well as to ensure how your linear measurements translate into the order of materials.

What is the mistake that people normally commit when determining linear feet?

The most prevalent error is that of not measuring all runs and mixing up measurements units without converting them appropriately. Always ensure you are doing your sums twice and include allowance to cuts and wastes.

Alex Morgan is a home improvement enthusiast from the U.S. who loves simplifying complex calculations for builders and DIYers. At TogCalculator.com, Alex shares easy-to-use guides and accurate calculator tools that help homeowners plan smarter projects. His goal is to make construction math simple, reliable, and stress-free for everyone.