Why the Concrete Curing Time Calculator Matters on Your Job Site

When pouring concrete for a foundation, a driveway or a slab the most important question is always: When is it ready? One can easily think that making the concrete look solid in a few days or two is enough and the job is complete. However, the real work is the process of curing. This is a chemical reaction which is termed as hydration. It is this reaction that develops the final strength of the material. Hurrying through this step will result in poor, fractured and broken concrete.

- The Science Behind the Cure: Factors for the Concrete Curing Time Calculator

- Type of Cement

- Benchmarks: Key Milestones for Use

- Milestone 2: Removal of Vehicle Traffic and Form (Service Strength).

- Milestone 3 full design strength (The 28-Day Mark)

- Case Study: Accelerated VS Delayed Curing

- Case B: Warded-off Residential Driveway.

- Practical Steps to Optimize Your Cure

- Admixtures, Technology, and Optimization

- FAQs

A concrete curing time calculator helps you have realistic time tables. It is a must-have tool to control your schedule, budget. Moreover, the overall sustainability of your construction project depends on this. It will also ensure the sites are safe and efficient. Initially, you need to understand the concept of setting and curing. Setting is just the initial stiffness. But curing is a long process that may require weeks.

The Science Behind the Cure: Factors for the Concrete Curing Time Calculator

To use any concrete calculator, you will have to understand the core factors. The strength of concrete is measured in compressive strength (psi or MPa). And this measure depends on how good the management of the chemical hydration reaction is.

Water-Cement Ratio

This is the most important aspect. Water- cement ratio (w/ c) is the ratio of water weight to cement in the mix.

- The lower the w/c ratio the greater the potential strength. The negative is that the mix is harder and tougher to manipulate.

- The greater w/c ratio the easier the concrete can be poured. But when the excess water evaporates it makes internal pores, which leaves a weaker product final.

Ambient Conditions and Temperature

The rate of the hydration reaction is directly proportional to temperature. It is equivalent to the accelerator or the brake.

- Warm weather (around 70 F or 21 C) makes the process very fast. Concrete will attain 70% of strength in a short period of time which is sometimes within the course of a week.

- Cold weather (below 50 F or 10 C) retards the reaction. When it becomes almost freezing, hydration is practically inhibited. Below 40 F (4 C), heating and insulated blankets should be used by the contractors. Stats: Decrease in temperature of 73 F to 50 F will double time to acquire 4,000 psi of strength.

- Quite often extreme heat results in too rapid evaporation of water, which causes surface cracking (plastic shrinkage) prior to sufficient strength having been built up.

Curing Method

These are the active measures taken to retain the moisture of the concrete following the pour. Constant wetness is necessary in order to prevent dehydration.

- Methods: Some of these methods are covering the concrete with wet burlap, ponding the surface with water or the use of liquid curing compounds that coats the surface.

- Improper curing: The failure to cure properly will lead to the surface drying too fast. Thus, producing a dusty, weak and brittle top surface that will wear off quickly. Stats: Continuous moist concrete that has been cured within 7 days is up to 40% stronger than concrete which has not been provided with protection.

Type of Cement

The kind of Portland cement that is utilized directly influences the cure rate.

- Type I: General-purpose cement. Applied to the majority of common applications.

- Type III: Stylish high early strength cement. It is prepared to develop strength at a very rapid rate. This is applied in cases where the time line of the concrete curing time calculator is to be shortened. Mostly in a tight deadline or cold weather.

- Types II and IV: Specialty types, such as environments which require moderate sulfate resistance or low heat generation, may have slower initial cure time.

Benchmarks: Key Milestones for Use

Contractors observe three major milestones since they know when concrete is firm enough to perform various tasks.

Milestone 1: Foot Traffic

- Time: Generally, 24 to 48 hours.

- Use: The surface is not so soft as to cause serious damage to a walker. Only light traffic.

- Caution: Do not place all heavy equipment and vehicles over the slab to prevent permanent damages.

Milestone 2: Removal of Vehicle Traffic and Form (Service Strength).

- Time: The average minimum is 7 days. At this stage, the majority of mixes have reached a stage of approximately 60-70 percent of their ultimate design strength.

- Use: Formwork may be safely removed. Traffic of light-vehicles (such as passenger cars) can be permitted, however, heavy construction loads are to be avoided.

Statistics: It is a fact in the industry that 70 percent of final, specified 28-day strength is usually obtained by Day 7 under optimal curing conditions.

Milestone 3 full design strength (The 28-Day Mark)

- Time: 28 days. This is the actual industry standard of the concrete to have its complete, intended compressive strength.

- Use: The building is prepared to carry its maximum load or full service i.e. heavy machinery or long-term car parking.

- Note: Hydration is basically finished in the period of 28 days, but concrete keeps gaining strength at an extremely slow rate during the following years.

Case Study: Accelerated VS Delayed Curing

The largest variable variables in the output of the concrete curing time calculator are material choice and temperature management. The two opposite examples are demonstrating the vitality of site conditions:

Case A- Accelerated High-Rise Foundation.

It took a team of people 7 days to achieve 4,000 psi (28 Mpa) to accelerate the time in which they were constructing their multi-story structures. They employed Type III High Early Strength Cement with a mixture of chemical accelerators. The situation was perfect, with an average of 65 F (18 C), and they used severe curing measures (misting and insulated covering). Findings: Day 7 Strength tests verified that the concrete had surpassed the 4,000 psi target. The saves of the team were one complete week on the construction list.

Case B: Warded-off Residential Driveway.

In late autumn a driveway was poured by a contractor with standard Type I Cement and a 3,000 psi (21 MPa) superego. The temperatures were often as low as 35 F (2 C) at night, but simple plastic covering was applied. Findings: Strength gain was greatly retarded owing to low fluctuating temperatures.

At the 7 days’ point, the concrete was only 30 percent of the intended strength. The homeowner was informed that 35 days were set before loading the vehicle and that was 25 percent more time than the usual time to avoid structural damages as a result of premature loading.

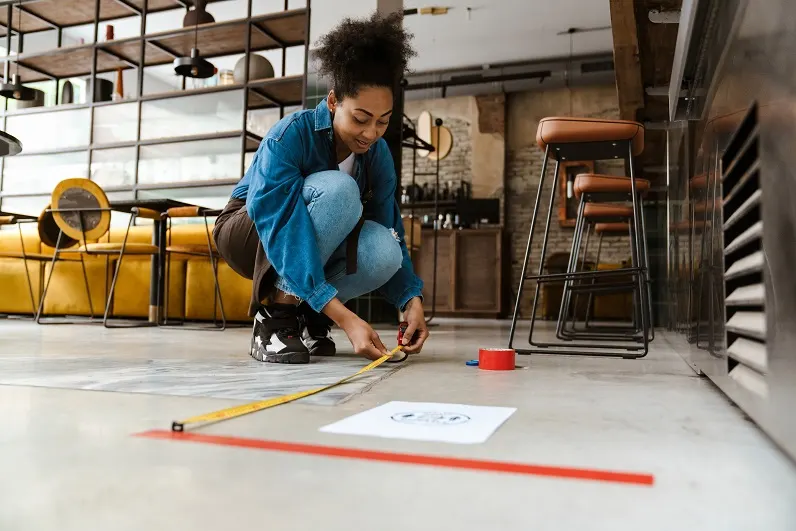

Practical Steps to Optimize Your Cure

Since the concrete curing time calculator is a predictive tool, your actions on site are key to success.

- Plan Ahead: Always check the weather forecast for the five days following the pour. Have curing blankets or heating equipment ready if freezing is expected.

- Cure Immediately: Begin your curing technique as soon as the surface water sheen (known as bleeding) disappears. Do not wait.

- Protect the Area: Use temporary fencing and clear signage to protect the newly poured concrete. Accidental early loading from cars or equipment is the leading cause of initial structural failure.

Admixtures, Technology, and Optimization

Modern concrete often includes admixtures chemicals added to alter its properties and control curing speed.

- Accelerators speed up hydration, useful in cold conditions.

- Retarders slow down the setting time, essential for hot weather or very large pours.

- Water Reducers (Superplasticizers) allow for a lower w/c ratio while maintaining flow, resulting in stronger concrete that cures faster.

If you want to know deeper about the science of cement and water interaction, check out Federal Highway Admission page, it offers comprehensive knowledge.

FAQs

How long does concrete take to fully dry?

Focus on curing, not drying. Concrete needs moisture to gain strength. It achieves its full design strength after the chemical hydration reaction is complete, which takes 28 days.

Can I speed up the concrete curing time?

Yes. Use Type III Cement or accelerator admixtures. The most effective way is maintaining continuous surface moisture and a consistent, warm temperature above 70 ∘ F.

What happens if concrete freezes before it cures?

Freezing before reaching 500 psi (3.5 MPa) permanently damages the internal structure due to expanding ice. This results in a weak, crumbly surface that often requires removal.

Alex Morgan is a home improvement enthusiast from the U.S. who loves simplifying complex calculations for builders and DIYers. At TogCalculator.com, Alex shares easy-to-use guides and accurate calculator tools that help homeowners plan smarter projects. His goal is to make construction math simple, reliable, and stress-free for everyone.